Premium Top Rollers

Nachi Tekneka is one of the leading manufacturer, supplier and exporter of new generation TOP ROLLERS in India. We are producing the PREMIUM quality top rollers for the preparatory and spinning machineries. The top rollers are manufactured with shared JAPANESE technology. We are producing the top rollers for the machines Rieter, Truetzschler, Toyoda, Zinser, Suessen, LMW and Marzoli.

Features

- The raw material steel alloy of the roller is imported from Japan.

- The bearings used in our top rollers are from INA – Germany and IKO – Japan.

- The rubber cots are used in our top rollers from Accotex and Berkol.

Top Roller

- Thanks to ‘sub-zero treatment hardness method’ which helps to achieve great strength and sturdiness to the top rollers.

- This treatment is used in our top rollers which is used in Aerospace components.

- The hardness applied 58 to 60 HRC.

- The depth of the hardness applied to 2 to 3mm.

- It helps to avoid bend of top roller during heavy lapping.

- By having above advantages, the ‘Nachi Top Rollers’ can be used minimum of 3 to 4 cots mountings.

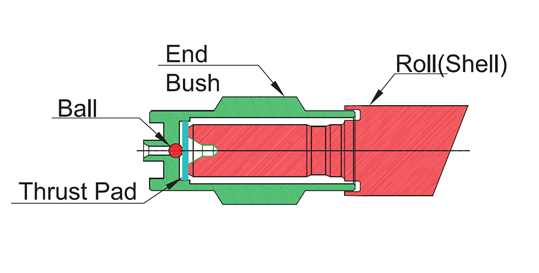

End Bush

- The conventional end bush easily gets high temperature due to friction between the top roller and end bush.

- The top roller is a rotating part, and the end bush is a non-rotating part. Therefore, the friction takes place between top roller and end bush which creates high temperature. This causes failure of the bearing in the end bush. When the bearing starts to worn-out, it also worn-out the end bush and top roller.

- The above all, causes the lifetime of end bush and top roller. More importantly this impacts on the imperfection on the sliver quality such as CV% and U%.

- Nachi developed end bushes with the ‘thrust pad’ and ‘ball’ arrangement to avoid friction between the top roller and end bush. Hence, the lifetime of the end bush and top roller are increased compared to conventional types and it also helps to maintain good sliver quality such CV% and U%.